Product Finder

The product finder helps you to narrow down the search for the right sensor, heater or IR-emitter. Start by selecting the product group.

At Innovative Sensor Technology IST AG we specialize in the development and manufacturing of temperature sensors, thermal mass flow sensors, humidity sensors, conductivity sensors and biosensors.

In addition to our standard products, we offer sensor adaptations to individual, customer-specific application needs - right up to the joint development of new technologies. IST-sensors are characterized by their accuracy and consistency in various measurement conditions. They are used in measuring instruments for various applications, such as med-tech, process control, automation, aerospace, test and measurement or biotechnology.

New products

Moisture-in-Oil Sensor

Frequently, it is necessary to monitor the condition of lubricants with the support of sensor technology. For such a monitoring function, IST AG has engineered the new Moisture-in-Oil sensor, a compact, digital humidity and temperature module (RH/T) that will measure the relative degree of saturation of water in %RH (water activity aw in %) in oils and fuels.

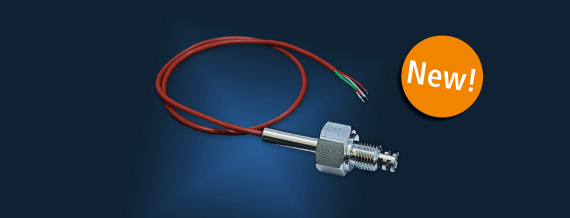

SFS Flow Module

Fast, continuous gas flow monitoring, suitable for gas dosing systems, manifolds and analyzers, with a response time ≤ 20 ms. The module is already linearized from factory with a reproducibility of 0.2 % and an accuracy of 2 %.

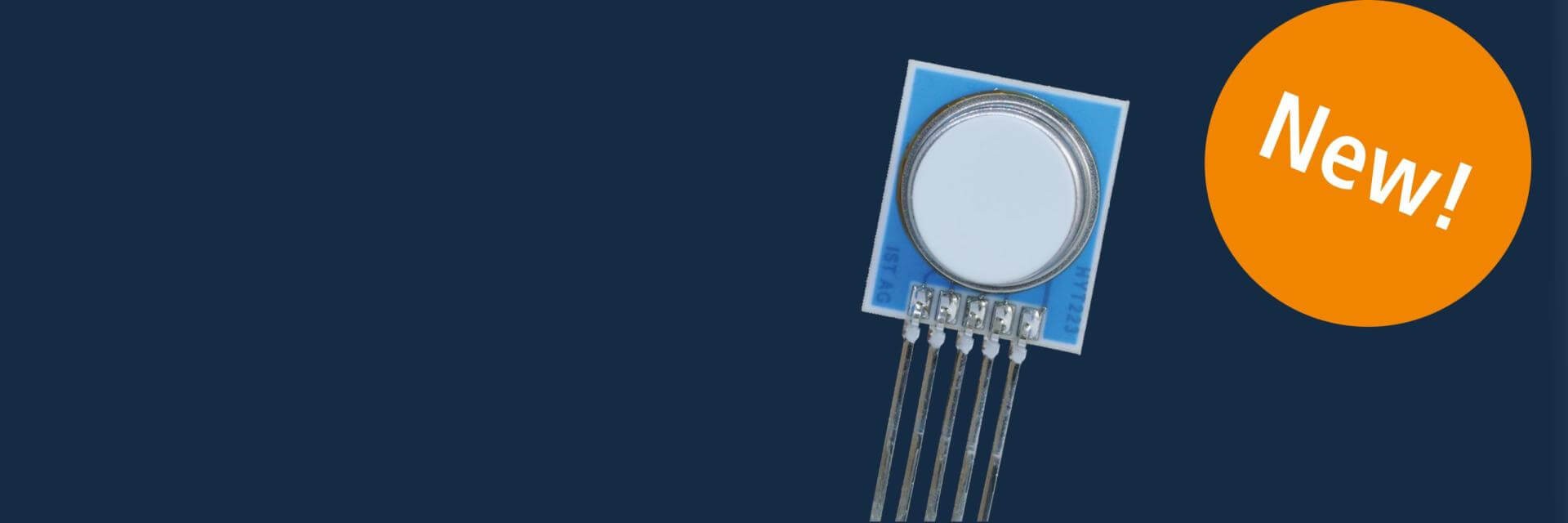

HYT 939 P with VOC protection

In industrial drying processes humidity measurement is vital in providing early warning of fluctuations in moisture content or for providing an indirect indication of how close dried materials are to their desired final moisture content.

IST AG’s HYT 939P with VOC protection provides the optimal solution for compact sensors in industrial drying applications.

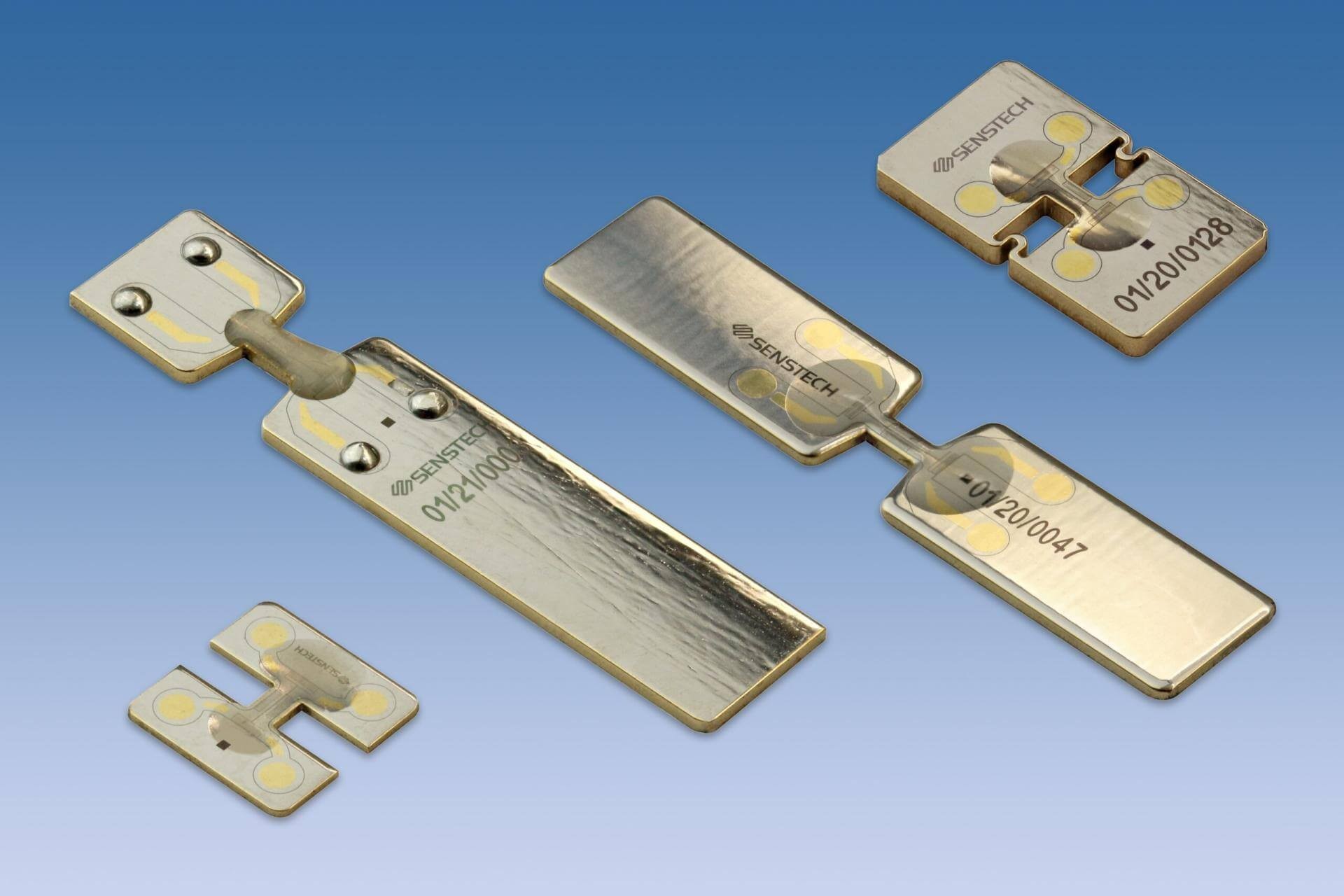

Force, torque and surface strain sensors

Physical thin film sensors for measuring large forces, shear stress, surface strain. Senstech is specialized in the development of standard and OEM sensor solutions for various measuring parameters, the application and structuring of thin layers as well as all other steps for the production of the sensor elements

Theodore LevittCreativity is inventing new things. Innovation is doing new things

Product highlights

Micro-Heaters

For precise, reliable and cost-efficient heating of solids, liquids and gases: our micro heaters are custom-built to fit your application's requirements.

Thermal infrared emitters

Thermal infrared emitters for gas analysis, material detection & spectroscopy are used in numerous applications across a wide range of industries.

Nucleic Acid Extraction

Spin Filter, Magnetic Beads, Smart Modified Surface or Polymer Mediated Enrichment: Automated or manual, find the right extraction technology and platform.

Our expertise

Our advanced expertise is driven by the challenge of being at the cutting edge of the industry. We continuously improve existing technologies by working closely with customers to find optimal sensor solutions for specific application requirements and by collaborating with a wide network of partners, including institutes and universities.

Tailor-made sensor solutions

We develop customized sensors, from minor modifications of standard sensors to complete new product development to meet the requirements of your application.

Flexible quantities and fast production

We produce various quantities of sensors in short development and production times.

Development and consultation

As a technology partner, we offer sensor technology development and consulting in our state-of-the-art facilities.

Support

Our experts offer support from vision through development to after-sales services.

Wide product range

We develop and manufacture sensors that are customizable across a wide range of products.

Partnership

We work closely with our customers to find the optimal sensor solution that meets the exact needs of their application.

Answer from the Customer Satisfaction Survey 2021I am very satisfied with IST and have known the company for over 20 years since I founded my company.

Customized Sensors

While you can find our standard sensors using the sensor finder above, contact us for a sensor solution tailored to your application requirements.

What our employees say about working at IST AG

IST AG has always encouraged and supported me in my endeavours. I have been able to further develop myself, take on new tasks and responsibilities and I am proud and grateful to be part of this great team.

Andrea Rüegg

Assistant to the CEO

@ IST AG since 2001

I like the close cooperation with different departments and the accessibility of our top management. My work is always appreciated and IST is always open to new ideas.

Prend Rrasi, Teamleader Dicing & Welding

@IST AG since 2011