The Internet of Things (IoT) describes the scalable networks of Edge devices (sensors) that connect to the Internet to collect, process and exchange data; improving interactions between physical devices across various sectors, such as manufacturing, the connected home, transportation, medical and agriculture.

Additive manufacturing with laser application

An additive manufacturing facility with state-of-the-art equipment has high requirements to its process stability. A collection of IST's sensors can be directly integrated into the device and add high value to various functionalities, such as longevity, reliability and high precision.

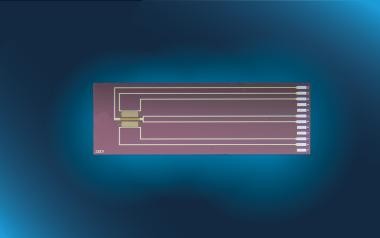

1) Gas Mass flow: SFS01

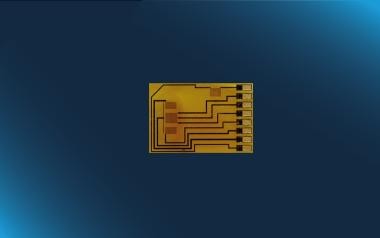

2) Gas supply flow & gas ratio control: SFS-DGF

3) Dew point monitoring: HYT 939P

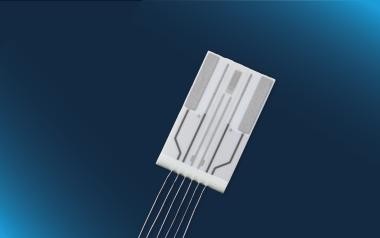

4) Temperature control and localized heating: Pt1000, Micro-Heaters

5) Filter control and air velocity: FS7

6) Humidity: HYT939 PTFE

The Collect – Edge device

To streamline the performance of Edge devices in IoT, IST has developed a number of specialized temperature, humidity, conductivity and flow sensors for these networks of physical devices, vehicles, and buildings embedded with electronics, software, and connectivity enabling them to collect and exchange data. IST Sensors in IoT also provide opportunities for a wide range of industries, including manufacturing, building automation, automotive, transportation, healthcare, agriculture and more. We offer our customers a wide range of sensor elements, modules and assemblies to implement IoT solutions that result in a faster time to market.

The Sensor provides the intelligence to sense, measure, interpret, and connect an internet gateway to the cloud. The data can be pre-processed with some form of analytics before it is transmitted for deeper data mining intelligence.

Larger IoT applications require a large array of edge devices in order to form a network of edge devices. In such cases, each edge device (node) needs to have a unique identifier in order to recognize and communicate with them effectively.

Industrial Drying

Industrial drying using compressed air

In a compressor-dryer-sensors-IoT control unit for an integrated compressor-desiccant dryer and pressure vessel, an IoT module is required to realize more prompt reaction to problems or reminder of scheduled maintenance, as maintenance is one of the challenges in this market. The compressed air is partly used on foodstuffs, a minimum dryness is needed to prevent bacteria from multiplying. (pressure dewpoint @ -26 °C).

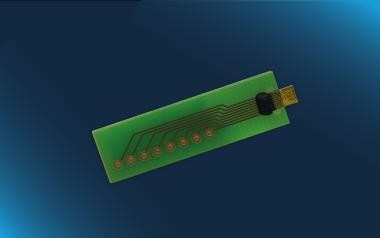

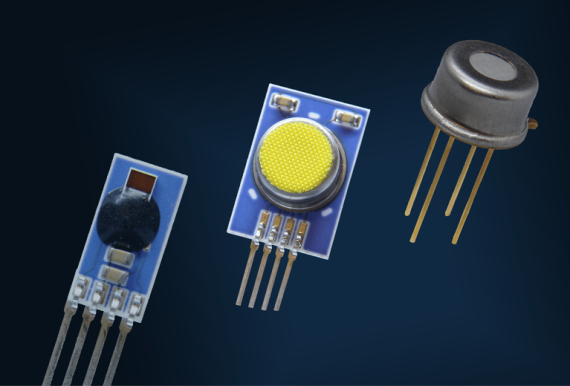

Pressure-tight HYT939

IST AG’s HYT939 Humidity sensing module, customized for the application, is used to validate the dryness of the air during the measurement of the outgoing compressed air. The digital plug 'n’play IST AG HYT humidity modules are ideal for high measurement accuracy IoT applications and is also offered with a pressure tight packaging to 16 Bar. Precisely calibrated, the HYT Module combines the advantages of a precise, capacitive polymer humidity sensor with the high integration density and functionality of an ASIC.

Precise and customized calibration

The I²C digital software output from the module conditions and delivers the measured physical data in digital form

The HYT sensors are provided in exposed sensor element versions, as well as two filter cap versions (mechanical protection) for simple integrations into IoT Edge devices operating in extreme environments such as Agriculture (soil), Transportation, smart cities etc. Our three HYT models can be delivered with a tailored calibration.

Find the right sensor

Ask our experts