Major developments in personal healthcare and diagnostic analysis, together with the ability to screen health issues early and deliver effective and personalized treatment options, is changing medical care as we know it.

Medical care increasingly relies on technology-aided systems and smart medical devices. Biomedical sensors for example, detect specific biological, chemical, and physical processes and then process this data, and are components in systems that process clinical samples, such as “lab-on-a-chip” devices. Biomedical Sensors are also often used to monitor the safety of medicines, food, environmental conditions, and other substances.

And it is precisely in biomedical that environmental and biological sensors enable this high functionality.

Real-Time Remote-Health Monitoring Systems (RHMS)

Patient monitoring

Monitoring or providing patient treatment in real time is a fast-growing market. Through major advancements in biomedical technology, particularly in sensors, wireless networking, cloud computing and data storage, RHMS is becoming a feature of modern medicine. RHMS for the prioritization of patients with multiple chronic diseases (MCDs) plays an important role in sustainably providing high-quality healthcare services.

In-vivo monitoring

As temperature changes in pathophysiology monitoring are relatively slow; size, thermal capacitance and conductance of the temperature sensor encapsulation material dictates the choice of sensing technology for implantable single-use temperature sensors and microfluidic devices. For example, advances in motor neuro-prostheses will rely on sensor data to enable innovative feedback algorithms. The market is moving away from externally wearable sensors and moving to implantable sensors and sensor networks.

Miniaturized temperature sensors

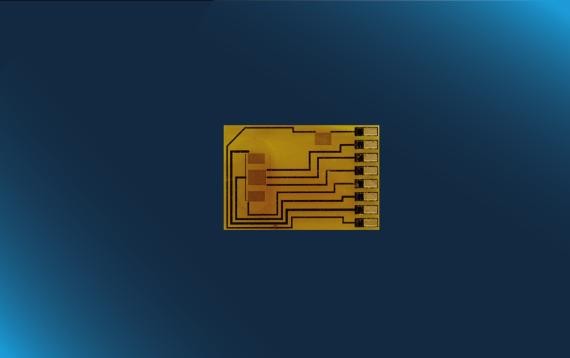

Platinum thin-film RTD temperature sensing elements with small size, long-term stability, and simple algorithmic signal processing, are the best choice of technology for medical temperature monitoring in real time These sensors can also be integrated within semiconductor devices designed specifically for these medical applications.

IST AG offers miniature surface mount sensing elements with Bondsens, the smallest SMD Pt1000 sensing element worldwide at 0.75mm x 0.75mm chip size. The sensor operates within a temperature range of -50 °C to 150 °C (according to IEC 60751) and is designed for automatic placement in high volume applications on printed circuit boards where long-term stability and interchangeability are important.

We also offer custom RTD platinum sensors fitted to medical application-specific requirements in terms of specified TCR values, nominal resistance, dimensions, housings and connections amongst other variations.

Find your Temperature Sensor

Monitoring Breath Intake - respiratory rate (RR)

Respiratory monitoring

Respiratory rate (RR) is a medical measure representing ventilation (air moving in and out of the lungs). A change in RR is usually the first medical sign of patient deterioration as the body attempts to maintain oxygen delivery to the tissues. A monitoring device will detect the early signs of patient deterioration and trigger an alarm. High prevalence of asthma and chronic obstructive pulmonary diseases (COPDs) are some of the major factors driving the demand for respiratory monitoring devices.

Breath analyzers

Conventional techniques for measuring respiration parameters require sensors in contact with the subject. Measuring techniques based on the monitoring of several parameters sampled from inspiratory and/or expiratory flow (e.g., temperature, rH, CO2, and flow) are widely used. Spirometers, Peak Flow Meters, and Gas Analyzers are used to monitor and regulate breathing cycles. To evaluate a breathing cycle, these devices require flow sensors with an extremely fast response time and airflow direction detection.

Calorimetric flow sensors

IST AG`s calorimetric flow elements MFS02 & SFS01 are designed specifically to measure the flow volume of each breath intake and exhalation. The MFS02 thermal flow sensor can be used in a wide flow range from 0 to 150 m/s (CTA mode) and in a temperature range from -40 °C to +80 °C. The SFS01 is particularly suitable for low flow velocities up to 3.5 m/s (in gases). This sensor displays rapid measurement results of the flow rate as well as the flow direction.

The Silicon Flow Sensor SFS01 offers a very fast response time (<5 ms), very low energy consumption, and easy system integration including temperature compensation.

Sensors for respiratory care - Anaesthesia gas blender

Respiratory Care

An increase in the number of outpatient surgeries, rising preference for inhaled anaesthetics and increase in the number of well-equipped multi-speciality hospitals and surgical centres is driving demand for anaesthesia delivery machine to administer the calculated and exact amount of anaesthesics.

Dosage monitoring in anaesthesia gas blenders

An anaesthesia gas blender is the main component of an anaesthesia delivery machine, a medical device which mixes two or more gases and provides constant and controlled anaesthesia during surgery. It controls the desired air/oxygen ratios and blends them with nitrous oxide and other anaesthesia gases in a specific amounts to be delivered to the patient. The anaesthesia gas blender comes with electronics for automated handling, to control the flow of gases. A switch or a controller based on an FS7 flow sensor from IST AG, can easily be implemented with relatively simple electronics to accurately measure flow in the Gas blender.

FS7 with housing

With simple signal processing and calibration, the FS7 sensor demands low efforts on signal processing and calibration. The sensors are available as bare chip as well as with easy to integrate housing options for various applications.

Furthermore customized adaptations are available on request.

Find a flow sensor

Monitoring membrane processes separating ionic compounds

Blood purification is the core component for medical devices providing artificial kidney or liver functionalities that are crucial in the management of patients with multiple organ disfunction syndrome (MODS), and is usually performed intermittently. With recent advances in medical science, it is now possible to perform such blood purifications therapies continuously (24/7) for critically ill patients. Blood purification methods can also be effective at treating patients with COVID-19 by reducing concentrations of various pathogens, cytokines, and other inflammatory agents in the central blood stream.

Measuring electrical conductivity is a fast and easy method to monitor indicative parameters in such membrane filter processes that separate ionic compounds dissolved in liquids. For example, in extracorporeal hemodialysis machines, electrical conductivity monitoring within the ultrafiltration process is a crucial control parameter.

The LFS1305 conductivity sensors a 4-electrode conductivity measurement scheme and features an integrated high accuracy temperature sensor to provide on board temperature compensation.

The planar sensor construction of IST AG's conductivity sensors (such as the LFS1305) is made out of biocompatible materials, ideal for a wide range of applications in biomedical devices where the handling of whole blood demands for minimal biofilm generation and minimal risk of clogging. This basic sensor design can be adjusted to specific applications and requirements. It features a wide conductivity and temperature range, provides a fast response time, optimal accuracy, high chemical resistance, and excellent long-term stability.

Customized adaptations are available on request.

Find a conductivity sensor

Point of care testing (POCT)

Point of care testing (POCT) can deliver rapid critical care test results in close proximity to the patient. When properly incorporated within the patient care process, POCT can translate to faster therapeutic intervention, reduced preanalytical errors, and improved patient care. The analysis of metabolic markers, such as glucose and lactate are gaining importance in POCT and monitoring. New and emerging applications with wearable and minimally invasive approaches to analyze sweat and interstitial fluid (ISF) aim to revolutionize monitoring in challenging situations, in critical care and home care with biosensors delivering the core functionality of such medical devices.

Critical care monitoring

In intensive care as well as during and post surgery, medical devices are able to provide crucial patient information to caregivers and doctors through the utilization of our biosensors. Such metabolic monitors generate an early warning alarm before diabetes, sepsis, and deteriorating liver function in critical care patients occur. Novel, patient specific bed side monitors are enabled by our miniaturized, multiparametric sensor systems performing measurements with whole blood as well as dialysate. Measuring both lactate as well as pyruvate in the cerebrospinal fluid (CSF) during open brain surgery is another field of application, where patients can benefit from intelligent, multi-parametric sensing devices with our sensor components providing the readout.

Blood Gas analyzer

IST AG ‘s robust enzymatic biosensors combine the reliability of electrochemical techniques with the specificity of biological recognition processes. This construction offers great advantages in size, cost, sensitivity, selectivity, and fast response for their application in Blood Gas analyzers. Our biosensors can be combined with a microfluidic flow cell or are cost-efficiently integrated in OEM consumables and cartridges to deliver stable readout.

Machine pefusion

Perfusion machines for organ transport play an invaluable role in making more donated organs available for successful transplantation. Normothermic (and hypothermic) perfusion machines provide continuous metabolic supply during organ transport. Within the perfusate media, a close control of glucose and lactate is ensuring ideal conditions for organ preservation as well as regeneration. Furthermore, glutamate, glutamine and creatinine readings allow to assess specific organ types during this often multi-day lasting machine perfusions. Our biosensors offer continuous multiparametric readout functionality to phacilitate such readings within automated and space efficient transportation devices.

Ask our experts