IST AG’s conductivity sensors can be operated in a wide conductivity range from 10 µS/cm-200 mS/cm. They are available with different chip sizes and cell constants for tailor-made sensors to fulfill our customers’ demands. Since one of our main competences is the development of customized sensors, we encourage our customers to reach out to us to discuss their application and requirements, so we can recommend a sensor with an appropriate geometry and cell constant.

Answer from Customer Satisfaction Survey 2021IST has a good quality sensors

Due to the wide range of applications for conductivity sensors, the entire conductivity range, from low to very high ionic concentration in solution is covered. Monitoring of coolant quality in e-mobility and fuel cells for example takes place in very low conductivity ranges whereas desalination plants or medical applications display high conductivity values.

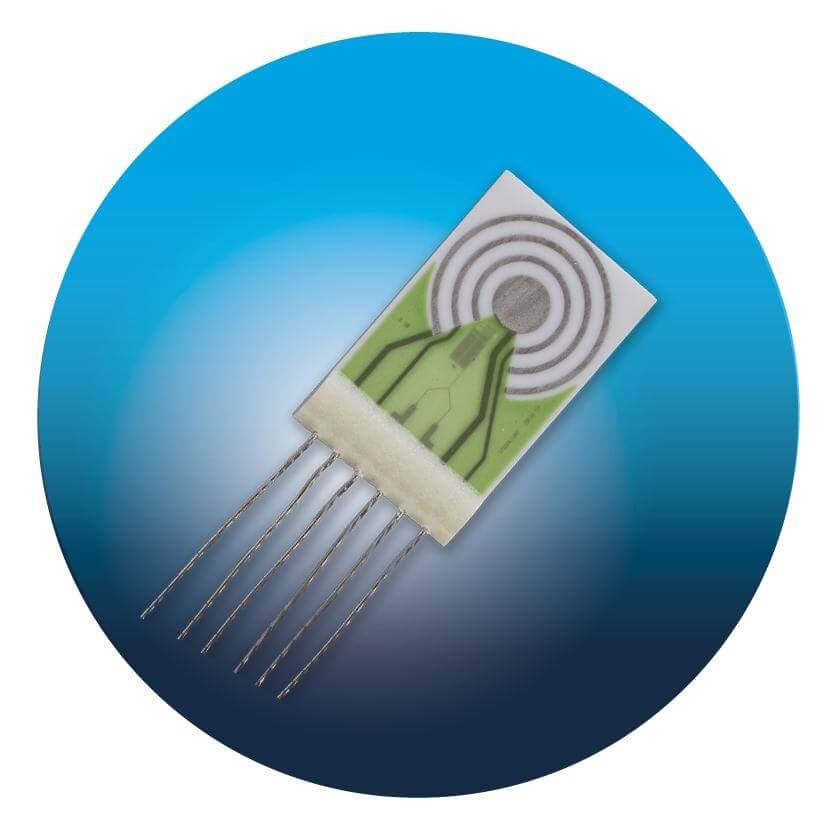

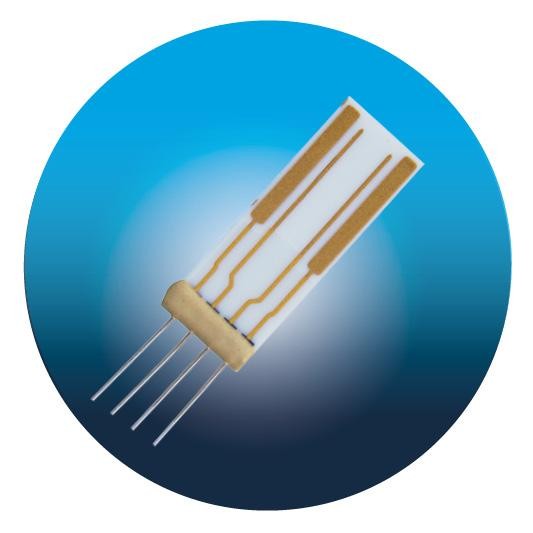

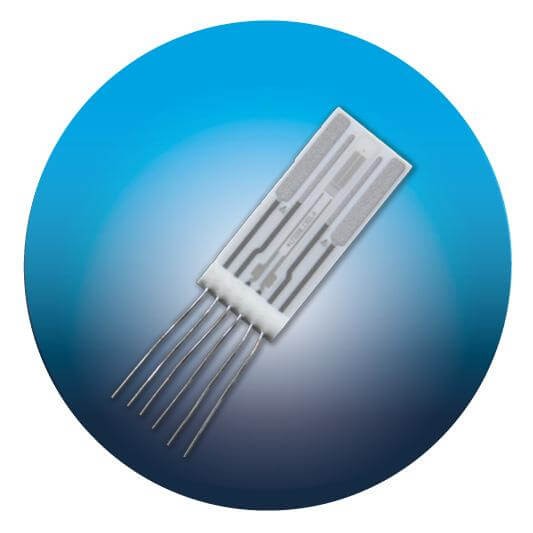

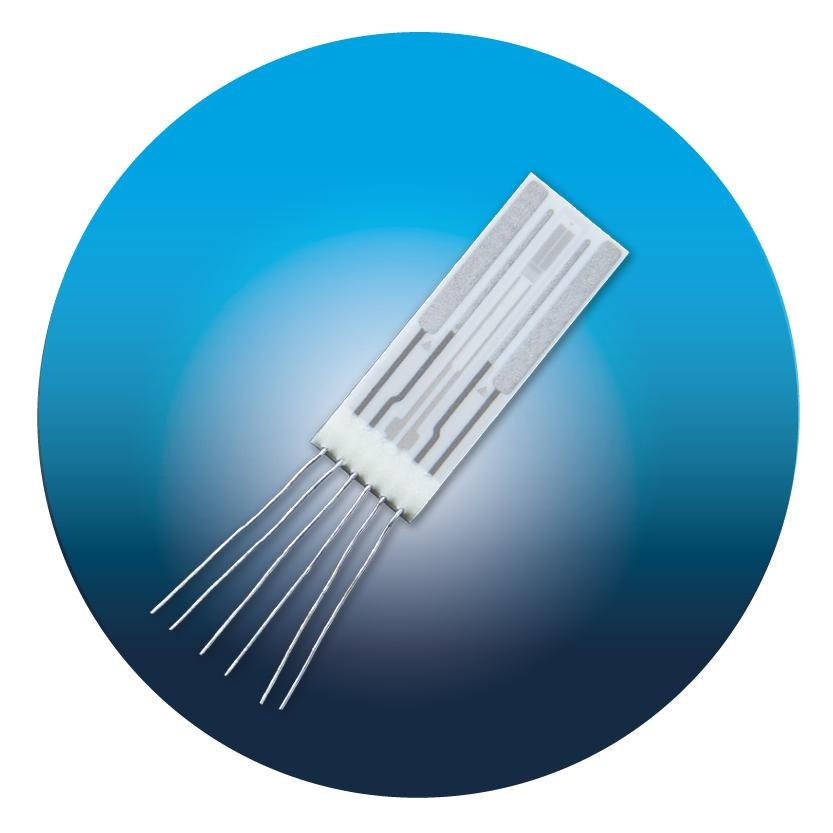

Measurements in different conductivity ranges call for various sensor designs. The precision of a sensor in different conductivity ranges is highly dependent on size of sensor chip and electrode layout. Furthermore, the mobility of dissolved ions is tremendously affected by temperature. This temperature effect requires either temperature control of measured medium or compensation of measured conductivity. IOur ceramic-based conductivity sensors can include a resistive temperature sensor (Pt1000 IEC 60751 F0.3), allowing for accurate compensation directly at point of measurement.

What conductivity sensors are used for

What conductivity sensors are used for

Conductivity measurements offer a simple and economical way to provide information on the ionic concentration and thus, the quality of measured medium of interest.

Conductivity sensors are widely used in industrial and environmental applications because they present a cost-effective, highly reliable measuring instrument that is independent of the sample medium.

Their applications range from water treatment and quality monitoring to leak detection in cooling & heat exchangers and condensers, to chemical processing, pharmaceutical and medical applications, food & beverage industries, and analytical laboratories.

Aqueous conductivity measurement

In ground- and wastewater treatment as well as in water quality monitoring, conductivity sensors are used to determine ionic concentration of solution to subsequently remove impurities to ensure that water quality is adequate for application.

This concept is used, for example, in water quality monitoring of drinking water treatment, irrigation in agriculture, aqua farming, and swimming pools.

Non-aqueous conductivity measurement

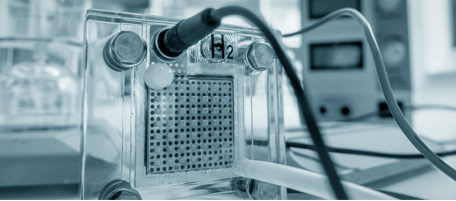

Applications are not limited to aqueous media. Conductivity sensors are also applied in non-aqueous media e.g. for quick, reliable, and continuous monitoring of coolant quality in e-mobility and fuel cells. Furthermore, they are incorporated in clean-in-place (CIP) and sterilization-in-place (SIP) processes, downstream processes to enhance quality of product.

Conductivity sensors will play a vivid role in upcoming IoT applications for example in healthcare and clinical diagnostics, agriculture and food & beverage. In medical devices they allow personal healthcare and diagnostic analysis, provide active drug dosing with feedback and are an essential part in dialysis. All above mentioned applications for conductivity sensors cover different conductivity ranges.

SI unit of conductivity

The SI unit of conductivity is Siemens per meters (S/m) and is mostly given in mS/cm or µS/cm. Ultra-pure water has a conductivity of 0.05-0.1 µS/cm, tap water 300-800 µS/cm whereas sea water shows high conductivity values up to 56000 µS/cm. Measurements in different conductivity ranges call for different sensor styles. The precision of a sensor in different conductivity ranges is highly dependent on the size of the sensor chip and the electrode layout.

Get your customized conductivity sensor

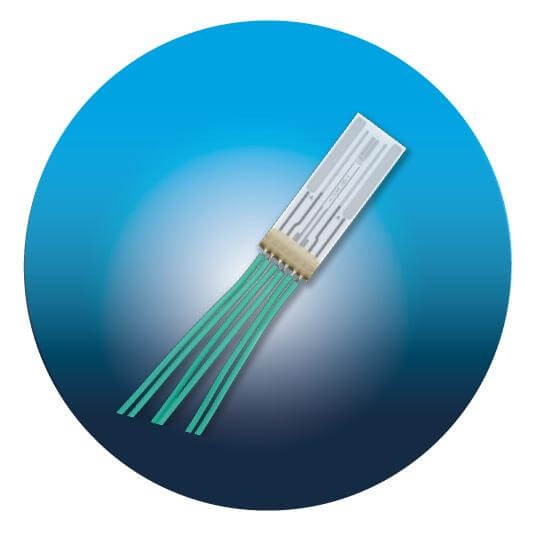

We provide different ways to further customize the conductivity sensors with respect to sensor design, contacts, wires, and housing.

IST AG sensors can be equipped with special housing for enhanced durability and easier installation. Different electrode materials are available and are chosen according to the customer’s requirements. Other common customizations are contacts and wires with different lengths, diameters, conductor materials, insulation materials and connectors applied at the wires´ ends.

Furthermore, we offer custom electrode configurations. Different electrode layouts, chips sizes and cell constants are possible and allow fine-tuning for enhanced accuracy of the conductivity measurement at certain conductivity ranges. To fulfill our customers unique demands for their special application our experts at IST AG will consult you with their knowledge and experience to find the appropriate conductivity sensor.