IST AG’s new Moisture-in-Oil Sensor – ideal for the continuous monitoring of water content in industrial oils

Oil is the lifeblood of many industrial plants and machines. It is used for cooling, lubrication, insulation, and power transmission. To operate a gearbox, a transformer or an industrial plant safely and stable over a long period of time, it is often necessary to monitor the condition of the lubricants with the support of sensor technology.

For such monitoring functions, IST AG has developed the new Moisture-in-Oil sensor. This is a compact, digital humidity and temperature module (RH/T) which measures the relative degree of saturation of water in %RH (water activity aw in %) in oils and fuels. This measurement method has a significant advantage compared to the measurement of absolute water content (in ppm H2O), because it always reflects the current condition and performance of the oil.

Every lubricant ages, this happens through degradation, additive degradation and impurities. As a result of aging, the oil's ability to absorb water changes in the long term and the lubricant's performance decreases, which, in the worst case, can lead to machine downtime and expensive repairs. In terms of preventive maintenance, continuous monitoring of the oil's current water absorption capacity becomes more and more important.

To ensure safe plant operation, such monitoring is used in those industrial areas where maintenance and machine downtimes are scheduled. Examples of moisture-sensitive systems can be found in ship engines and their gearboxes, in commercial vehicles, in the transformers of trains, and in power engineering in wind turbines and their generators. In industry, moisture monitoring can be used for large-volume oil reservoirs in large drilling and paper machines, and in smaller systems such as mobile oil filtration units.

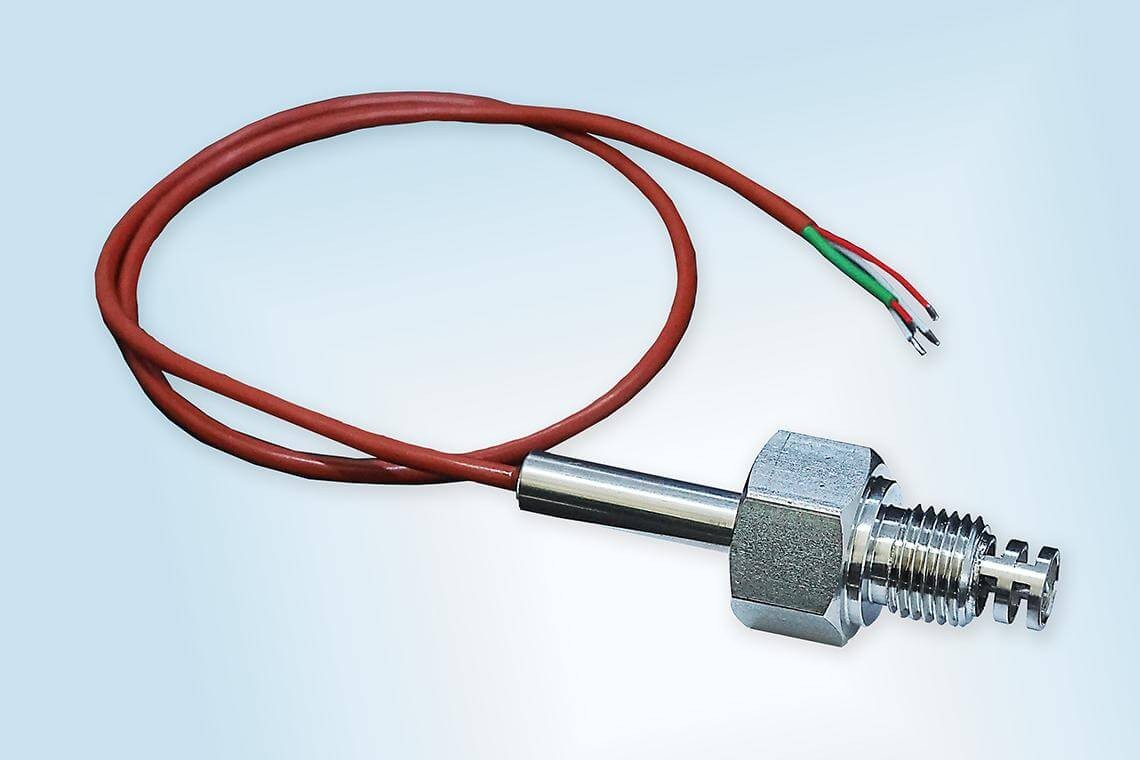

With its robust and compact screw-in stainless steel housing, the new Moisture-in-Oil sensor is ideal for use in an industrial environment. Via a universal, digital electronic interface (I2C), the sensor can be easily integrated into various measuring and monitoring systems. The sensor is delivered temperature compensated and calibrated and a test board with analog (0-10V) outputs is also available for evaluation purposes. Customer orientation is a major focus at IST AG, hence IST AG offers application-specific assembly and calibration solutions to manufacturers of measuring instruments for this sensor.

Key specifications:

- Continuous monitoring of temperature and degree of saturation of water in oil.

- Operating ranges: 0 to 100 % RH; -40 to 120 °C

- Reproducibility: ±0.2 %RH; ±0.1 °C

- Accuracy: ±3% RH; ±0.2°C

- Housing: 1.4571 stainless steel, M14x1.5mm thread

- Interface: digital I2C; 0.5 m cable