生产过程——从构思到成品传感器

.

设计

我们的顾问和工程师会与您讨论您的应用需求,以更好地了解您的需求。 也许我们数千种标准产品中的一种就足够了,或者我们进行细微调整或创建一个全新的产品。

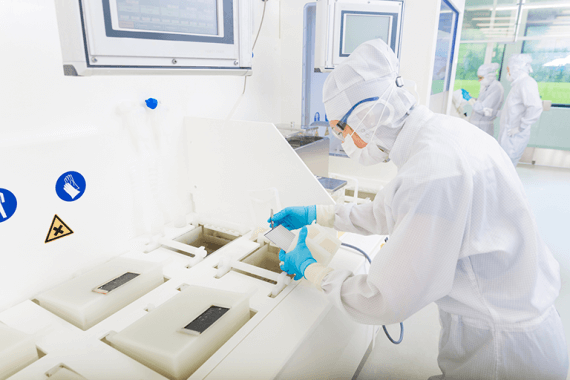

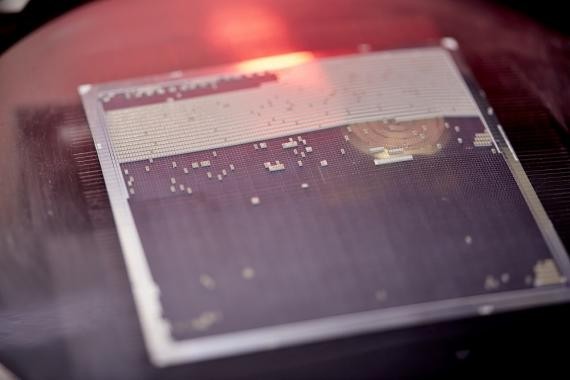

基板沉积

第一个生产步骤是沉积,使用溅射技术,以便在整个基板表面上覆盖一层薄薄的膜。根据所需的传感器类型,可以为覆盖层选择不同的材料、厚度和质量。

光刻

在这一步骤中,通过离心机将基材涂上光敏漆。我们所有的传感器结构都是在所谓的掩模上勾勒出来的:通过曝光,光线通过掩模被引到光刻胶上。被覆盖的部分不会被光照到,使涂层不被曝光。在随后的基片显影过程中,曝光区域的涂层被洗掉,未曝光的区域则留在基片上。

蚀刻

在蚀刻过程中,不需要的涂层部分通过蚀刻被去除。 两种不同的工艺用于蚀刻基板:离子蚀刻和湿化学蚀刻。

激光修整

IST AG使用激光修正或激光校准作为一种通过激光诱导材料变化来调整(修正)元件的方法。因此,通过减少蜿蜒结构不断增加电阻值,直到达到所需的值。

丝网印刷

在丝网印刷过程中,接触点用导电膏进行加固。这使得接触点和电触点之间能够更好地连接。此外,基材上还覆盖有不导电的浆料,这可以防止传感器因机械或化学影响而被刮伤和损坏。

切割

在切割的同时,基片被切成独立的条状,便于在传感器上焊接导线。

焊接

对于焊接工艺,IST AG 提供了焊接到芯片上的各种线材、长度和直径的可能性。 我们区分裸线和绝缘线。 为了增强焊接点并保护其免受机械损坏,在焊接区域涂抹了一种浆料,可提供出色的拉力。

测量

在最后的电气测量中,所有的传感器都要经过2点校准测量的检查。根据它们的精度,它们被分为不同的等级。

Dr. Florian Krogmann, Chief R&D OfficerOur versatile technological portfolio covers different substrate material choices, the use of thin- and thick-film technologies and patterning technologies as well as diverse test and assembly options.